EQUISCALE

Technologies

91 9173892314

Customer Support

Customer Support

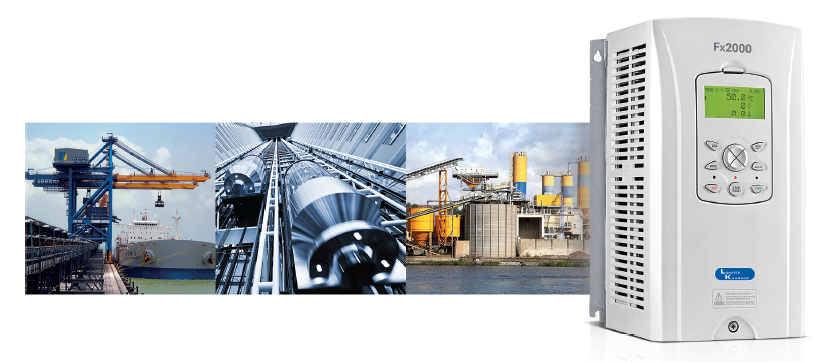

The Fx2000 generates powerful performance and meets your precise needs through several features: superior V/F control, V/F PG, slip compensation and sensorless vector control as well as closed-loop vector control.

The Fx2000 is perfectly suited for the toughest, most complex applications – cranes, plastic winders, high-speed elevators, cement kilns, crushers… and more. It handles loads up to 375 kW – HD / 450 kW – ND, and is engineered to keep your machine operating at optimum efficiency, even in the hot, humid and dusty conditions that characterize India’s industrial environment.

Main Features

› Range: 0.75kW to 375kW (HD)

› V/F control, V/F with PG, Slip compensation, Sensorless

Vector Control, Close Loop Vector Control

› Built-in Macro for Crane

› Starting Torque: 250% at 0Hz for Closed Loop

› Optional Smart PLC

› Optional Synchronization card

› Droop Control

› Conformal Coating complying to IEC 60721-3-3 class 3C2

(max) and class 3C3 (avg)

› Built-in RS485 Modbus RTU Communication

Applications

› Crane Hoist

› Crane Control LT / CT

› Winders

› Wire Drawing

› Plastic & Textile Machines

› Conveyors

› Compressors

› Extruders

› Fan

› Pump

Copyright © 2023 Equiscale India

Design by – Surat Web Solution